Defining the Digital Twin

A digital twin is a dynamic digital model of a product, process, or person, which analyzes existing business system data combined with real-world data. However, the value expands past the single digital model of an asset and is increasingly an underpinning element of an organization's digital transformation initiatives.

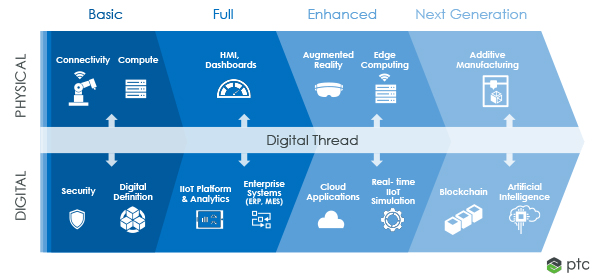

What Technologies Are Powering Current and Next-Generation Digital Twins?

There are innovative and emerging technologies spanning the digital twin stack creating tangible business value for smart connected products and smart connected operations use cases. However, each type differs in some form of functionality, complexity, integrations and technologies. The more technology systems added, the more ‘full’ the twin becomes, creating a digital thread, which adds challenges and opportunities for enterprise adopters and technology providers alike. Fundamental technologies up-through emerging ones span the physical and digital realms and enable increasingly valuable digital twin outcomes.

Basic:

There are a few core underlying technologies to fulfill table stakes requirements of a digital twin, surpassing lighter digital replicas and shadow categorizations in terms of value created. The physical asset must have the compute power to generate data and access to servers on-premises, in the cloud or at the edge for further processing and storage. The means to transmit this data requires reliable connectivity, which can come in the form of a LTE cellular network for geographically dispersed assets or a private low-power wide area network (LPWAN) in an operations deployment, among others. Any form of connectivity and device with internet access requires prudent security systems ensuring the integrity of the device, network, data, and server. At some level, there must be an accessible digital definition of the asset’s historical systems of records, which could include computer-aided design (CAD) models, product lifecycle management (PLM) integrations and increasingly real-time characteristics.

Full:

As the digital twin matures, there needs to be another layer of control and actionability to truly satisfy its term; 451 Research claims that ‘Twin implies that what happens to one happens to the other, in a mutable fashion’. To fulfill this, an IIoT Platform is required to connect, contextualize, and interact with these disparate physical systems as well as provide the virtual lens of the digital twin equipped with real-time sensor data and predictive analytics. Equally important context come from enterprise-wide business systems integrations at the organizational (ERP) and factory floor (MES) levels. This twin data is made available to a variety of front-line personnel through HMIs, supervisory computers, and dashboards.

Enhanced:

Emerging technologies will elevate functionality and related business impact in the near future. Edge computing and analytics enables the physical connected asset to locally process data, only sending prudent data off the device; a potentially critical factor for transmitting large 3D twin model data files and optimizing an asset’s compute power, bandwidth, and latency constraints. This local availability of twin data could then be extended to front-line worker’s increasingly available augmented reality headsets, portraying its digital representation and analytics alongside the physical asset for more immersive experiences. Cloud-based applications and IIoT simulation models further predict real-time machine outcomes based on historical and real-world performance data using the IIoT platform as an insight entryway to further power the digital twin.

Next-Generation:

The future digital twin will have a transformative business effect on revolutionary industrial product models like additive manufacturing. Product designers equipped with real-world operational performance via a feedback loop can adapt virtual product models and 3D print the next rendition or replacement spare parts. Technologies under the artificial intelligence domain, including machine learning and deep learning algorithms, are poised to reveal new operational insights and improve asset efficiencies from these abundant integrated twin data sources. Blockchain provides a decentralized digital ledger capable of validating data feeds from multiple stakeholders in the product lifecycle across a supply chain and create new insights for the twin, improving transparency and security.

Digital Twin Implementation Requires Partnership Ecosystems

Real-world application of this framework often comes in the form of partnership ecosystems; it's necessary to support the myriad of aforementioned technologies. Through the help of partners, Aachen University’s eLAB created a twin of its electric vehicle battery production lines, which reduced bottlenecks. The successful deployment included an IIoT platform to manage the connected battery line through role-based applications (PTC), connectivity and compute services (HPE) and the digital definition of assets on the line, simulation and HMI and enterprise systems integrations (NI, OSIsoft).

We anticipate the implementation of these technologies to have a transformative impact on manufactures in the near future. IDC forecasts that by 2022, 40% of IoT platform vendors will integrate simulation platforms, systems, and capabilities to create digital twins and 70% of manufacturers will use the technology to conduct simulations and scenario evaluations, reducing equipment failures by 30%.

While this opportunity is emerging, the key to creating value from will be integrating these essential technologies with one another. This is a challenging feat and successful implementations will require the right mix of technologies, domain expertise, and partnership ecosystems.

State of Digital Twin 2022

Learn how industrial companies are using digital twin across engineering, manufacturing, and service.

Read the Report